|

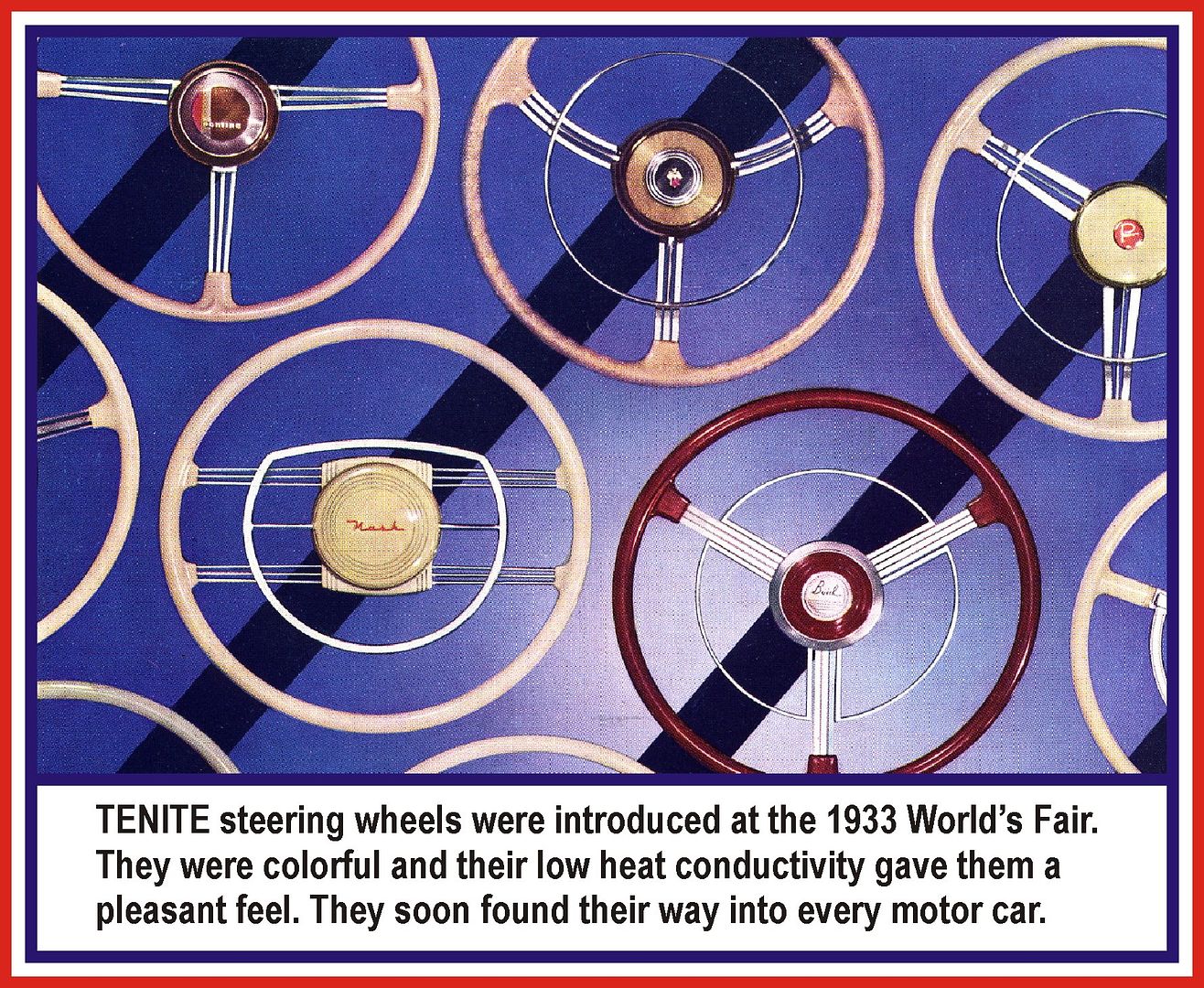

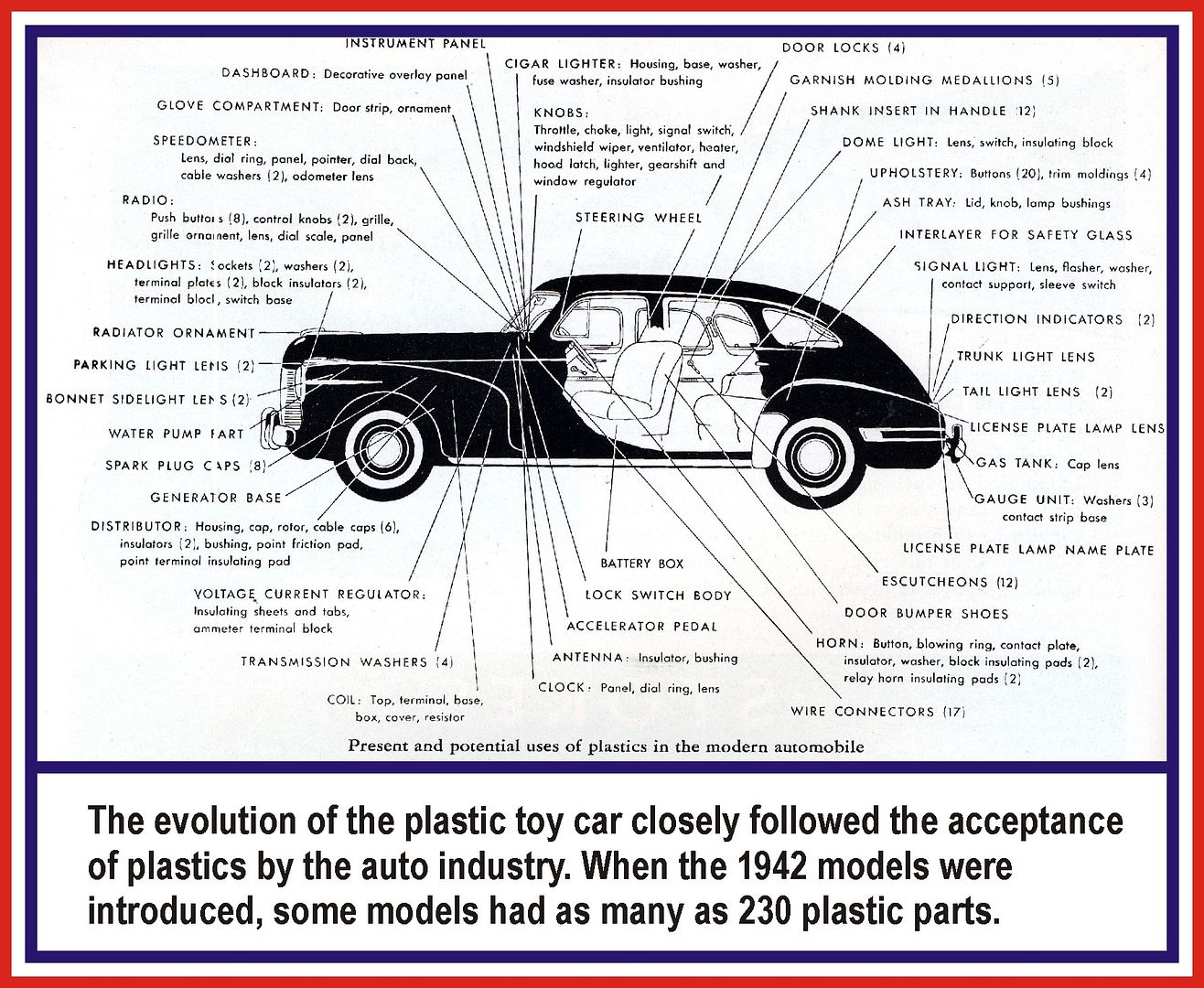

The evolution of the plastic toy car closely followed the acceptance of plastics by the auto industry. In 1932 the Tennessee Eastman Company introduced TENITE, the first commercial grade cellulose acetate that could be both compression and injection molded in unlimited colors. Injection molding was the plastic industry's answer to mass production and once a master mold was produced in hard carbon steel; millions of identical plastic articles could be swiftly turned out with only slight finishing operations needed. For Detroit, this meant knobs and other interior pieces that were never unpleasantly hot or cold to the touch, which often happens with metal when used outdoors. More importantly, it meant these pieces could be molded in colors to harmonize with the upholstery and other interior appointments. This was a big improvement over Bakelite, which could only be compression molded and was only available in brown or black. After their introduction at the 1933 Worlds Fair, TENITE steering wheels compression molded on metal cores in colors to match a car's interior quickly began to replace the standard hard rubber wheel, despite costing three times as much. By the mid thirties over eighteen models including Packard, Pierce Arrow, and Chrysler were using TENITE and the auto industry was well on its way to becoming the largest pre-war customer for plastics.

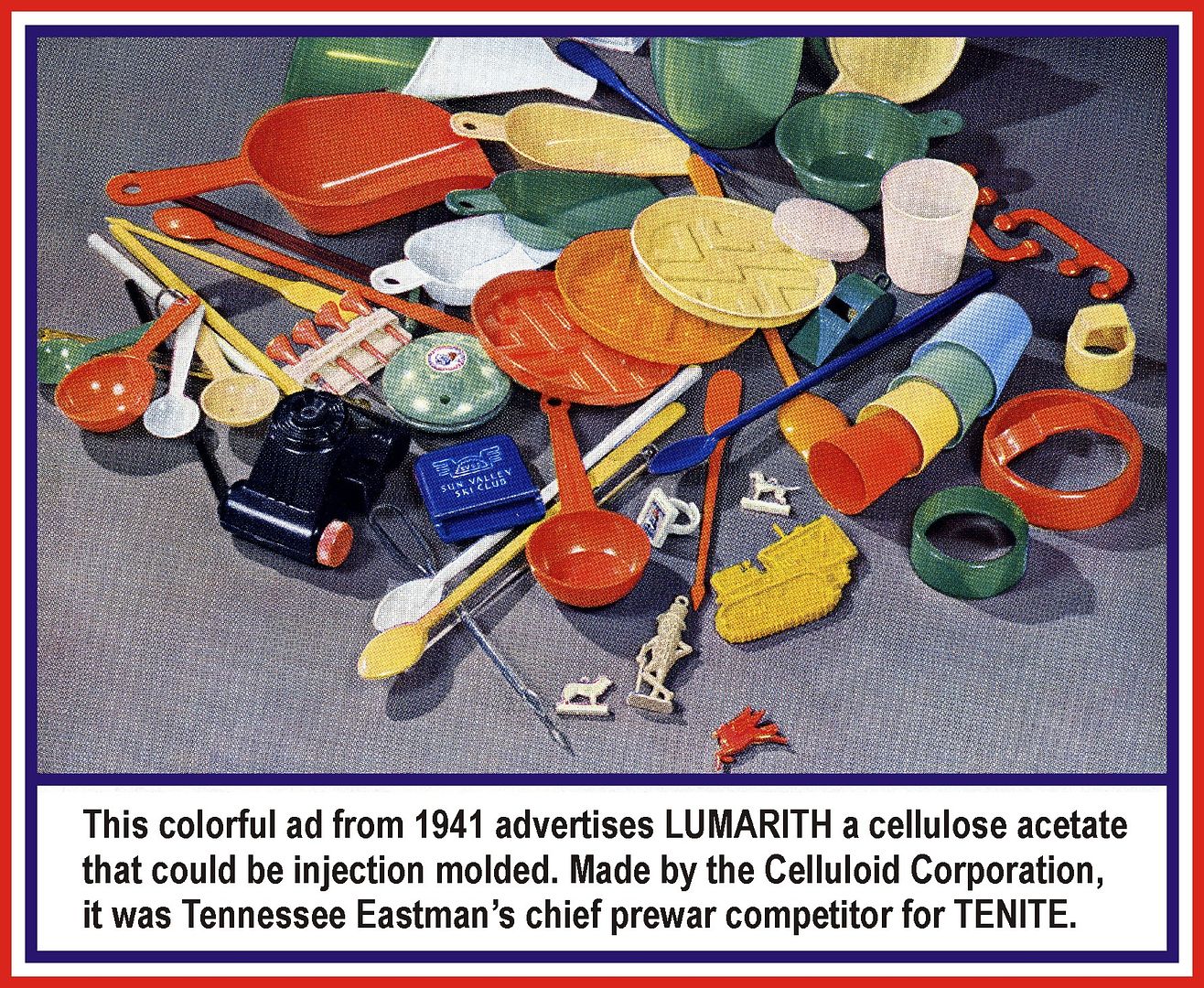

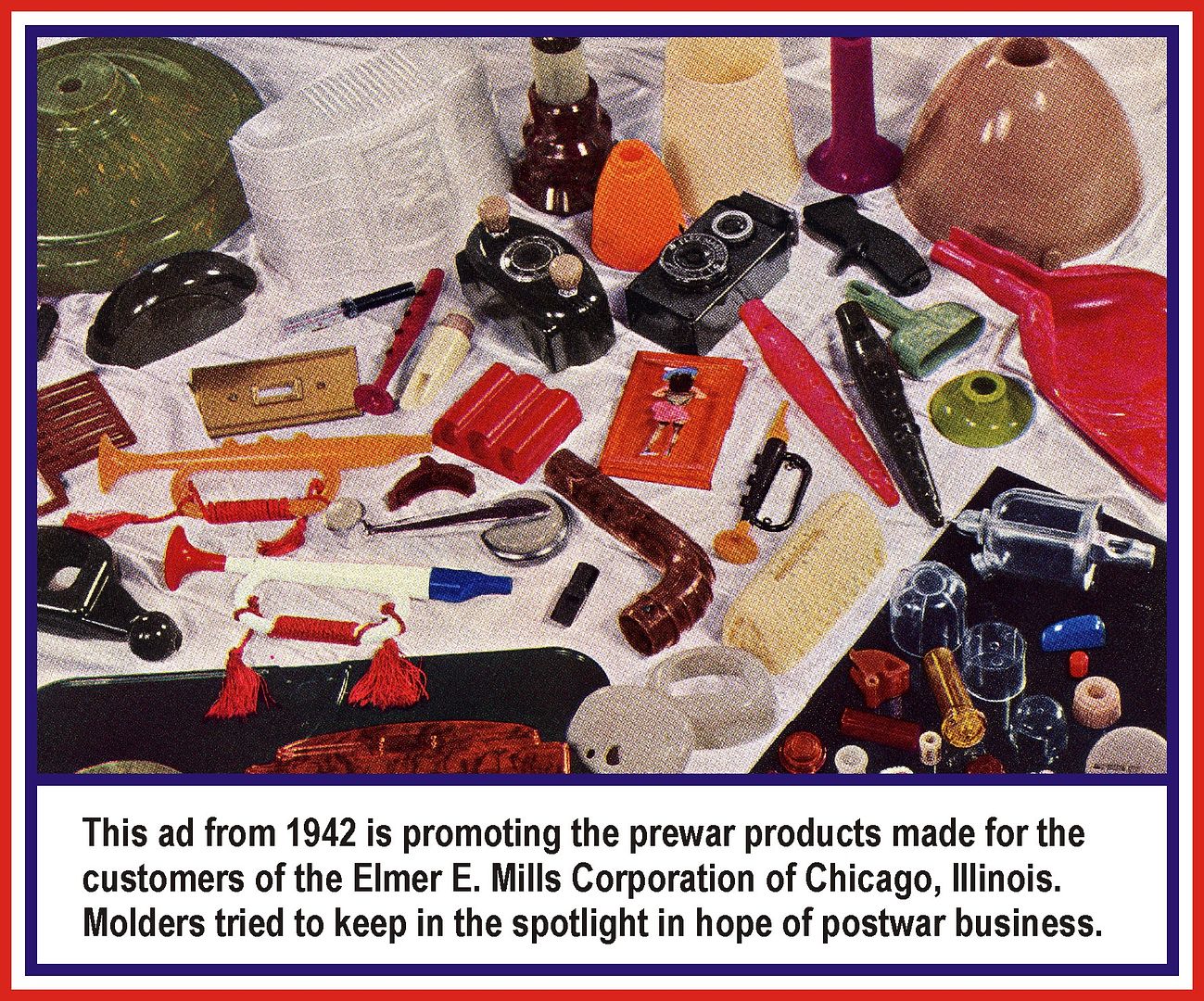

Plastics first appeared in the toy industry in the form of game pieces, chessmen, checkers, and dice. These items were made from fabricated sheets, or rods, and were cut, embossed, engraved, or turned to produce the desired pieces. With the introduction of cellulose acetates that could be injection molded like TENITE and LUMARITH, toy manufactures begain to slowly expand their use of palstics.

When the 1942 automobiles were introduced, the Du Pont Company reported that some models had as many as 230 plastic parts, including interior pieces, battery boxes, and other parts that called for resistance to electricity or the action of chemicals. It was obvious that the auto and plastics would soon become inseparable.

The first injection molded toy car was made out of cellulose acetate and was part of a new toy line introduced by the Kilgore Manufacturing Company at the March 1937 International Toy Fair held in New York City. Kilgore, located in Westerville, Ohio, had established itself as an innovator in 1932 when it introduced a line of ten-cent cast iron automobiles with real rubber tires in an effort to become the leader in the inexpensive toy category. Kilgore later became the first toy company to add injection molded TENITE handles to its cap gun line giving them that "pearl-like" look admired by would-be sheriffs and desperadoes.

Kilgore's new line of plastic vehicles was called "Jewels for Playthings" and included a sedan, coupe, taxi, express truck, and airplane. The line got its name from the "jewel-like" luster of the plastic. With a suggested retail price of only five-cents each they were one of the big toys hits of 1937.

While one could argue that at least three of the four vehicles were inspired by the 1937 Ford, Kilgore was careful not to give credit to any manufacturer. This policy of anonymity was adhered to by most plastic toy manufacturers who preferred to call their latest creations names like Aerocar, Auto-Mite, Jet-Job and Plasticar rather than Cadillac, Chevrolet, Buick, or Ford.

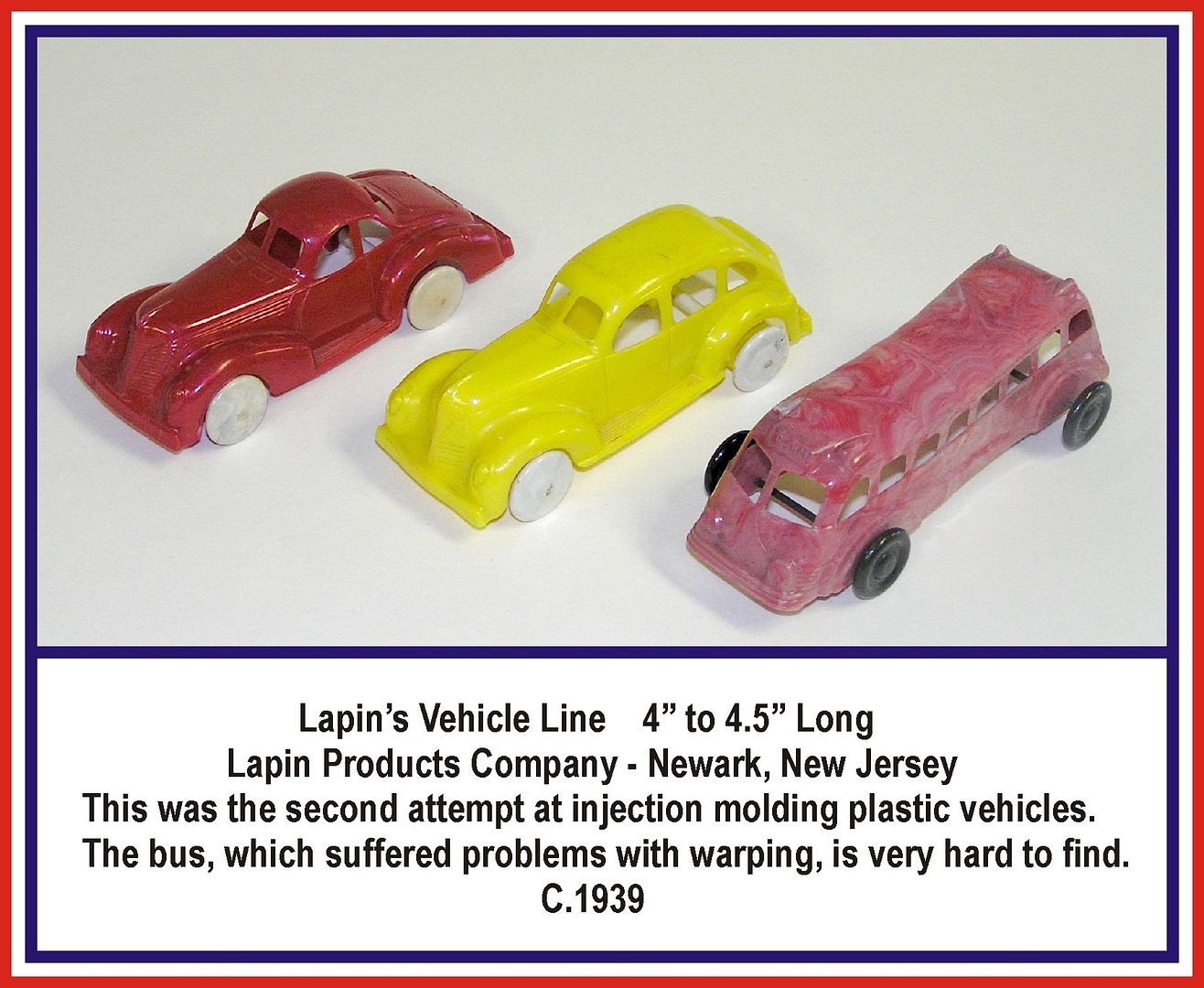

The "Jewels For Playthings" line's success caught the rest of the toy industry off guard and it would be not be challenged until 1939 when the Lapin Products Company of Newark, New Jersey introduced a sedan, coupe, and bus of its own. These would be the only prewar plastic vehicles offered, as the plastics industry was destined to play an important role in the war effort.

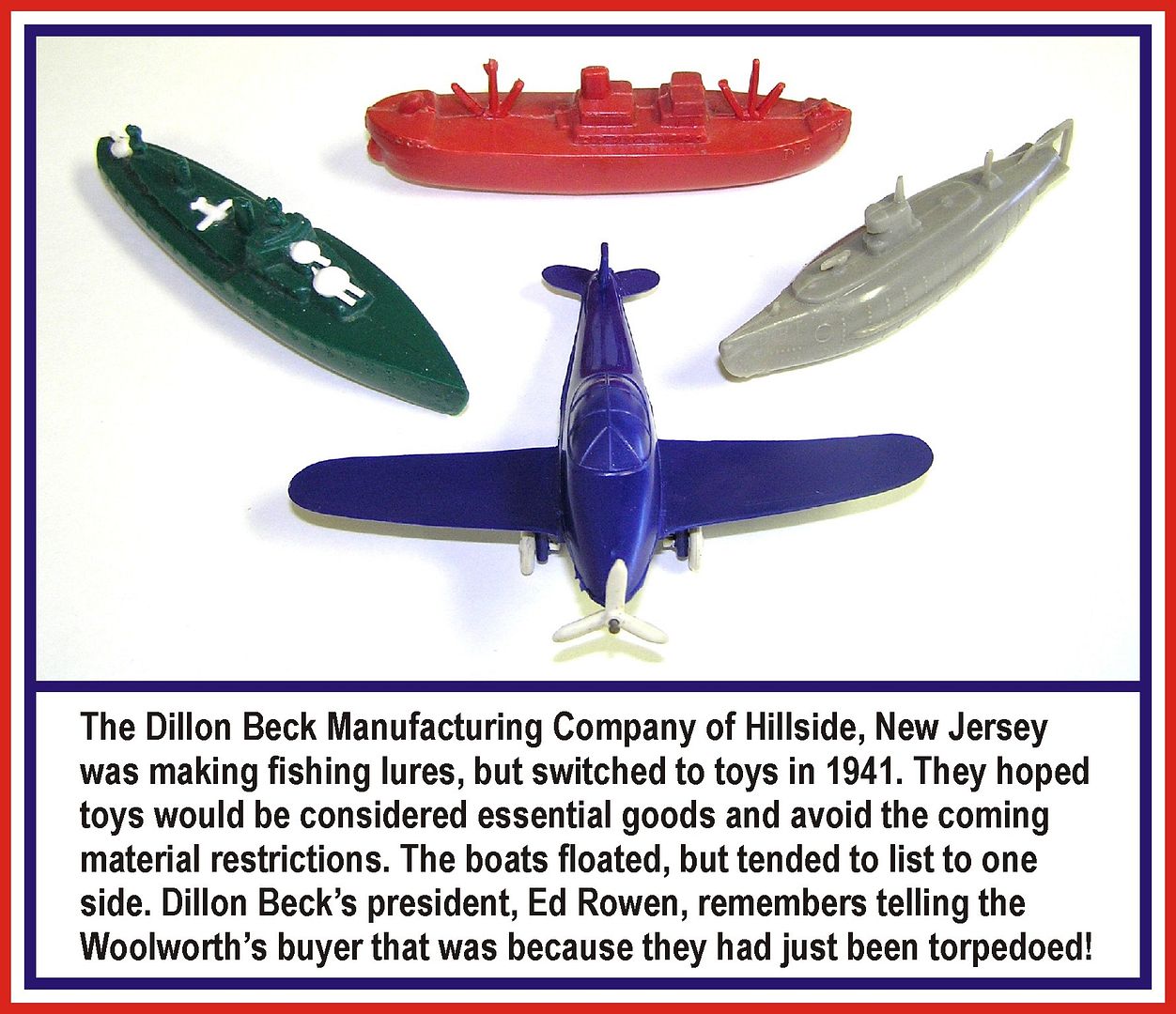

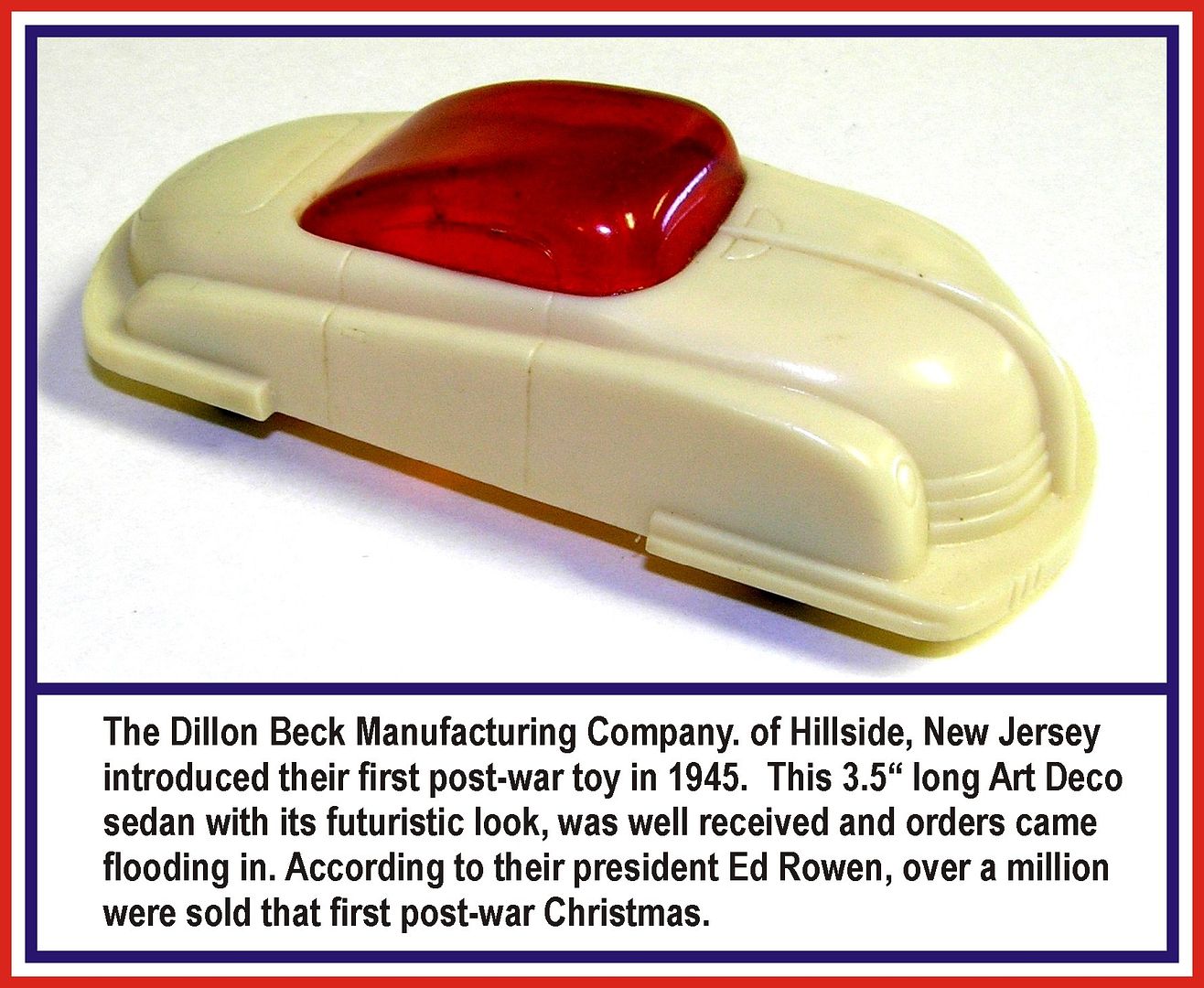

The next big news regarding plastic toys, came in 1941. That was the year the Dillon Beck Manufacturing Company of Hillside, New Jersey introduced the first plastic boats and the second plastic airplane. The company, under the direction of Daniel Dillon and Edward Rowen, was previously making Sure Catch fishing lures and marketing them under the clever slogan, "Wanna Catch The Limit" As the situation in Europe grew worse by the day, Dillon and Rowen knew that it was only a matter of time until the metal components needed to complete their plastic lures would came under government regulations. In 1940 a decision was made to switch production to toys in hope that they would not be classified as nonessential, because they helped preserve Young America's way of life.

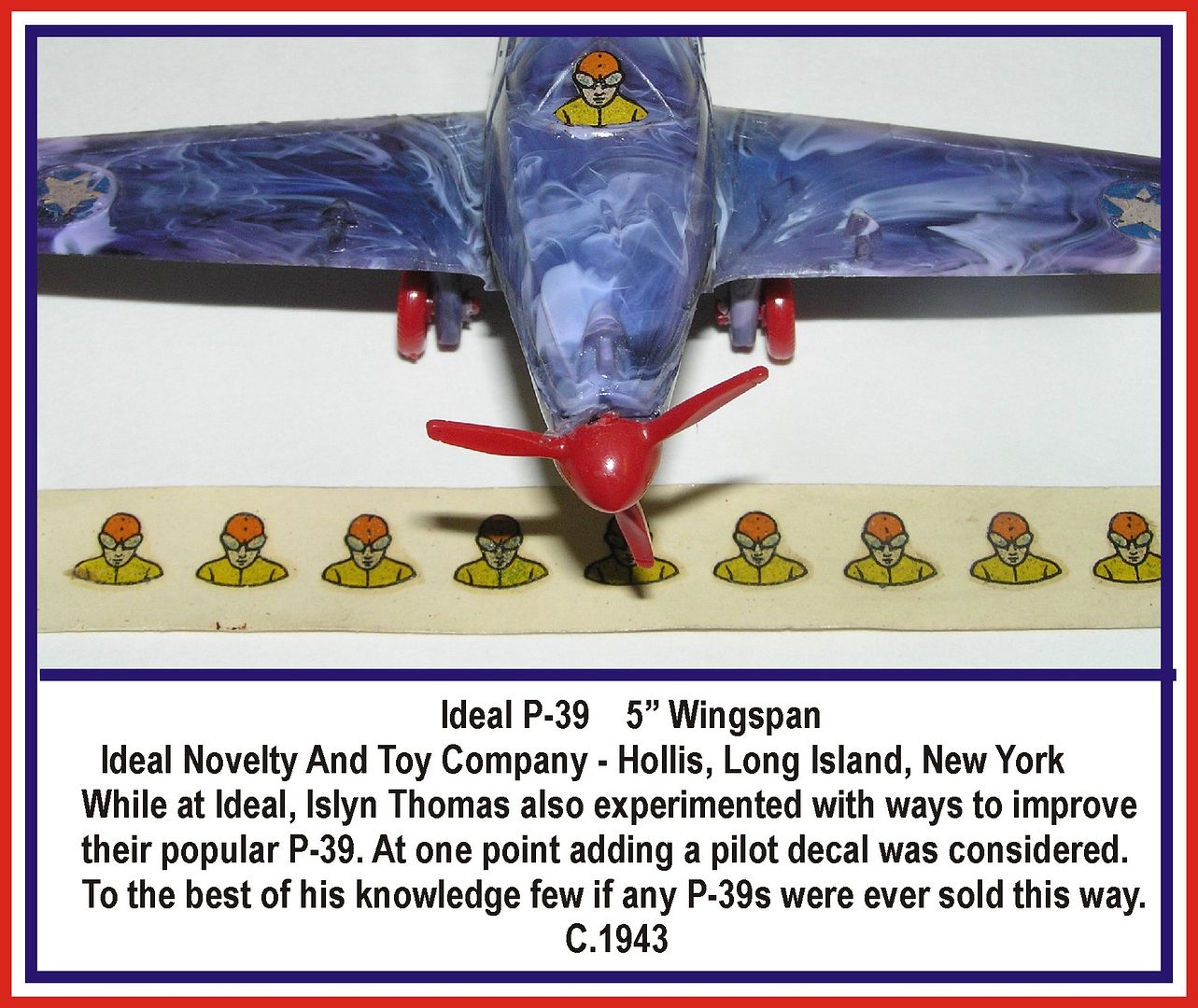

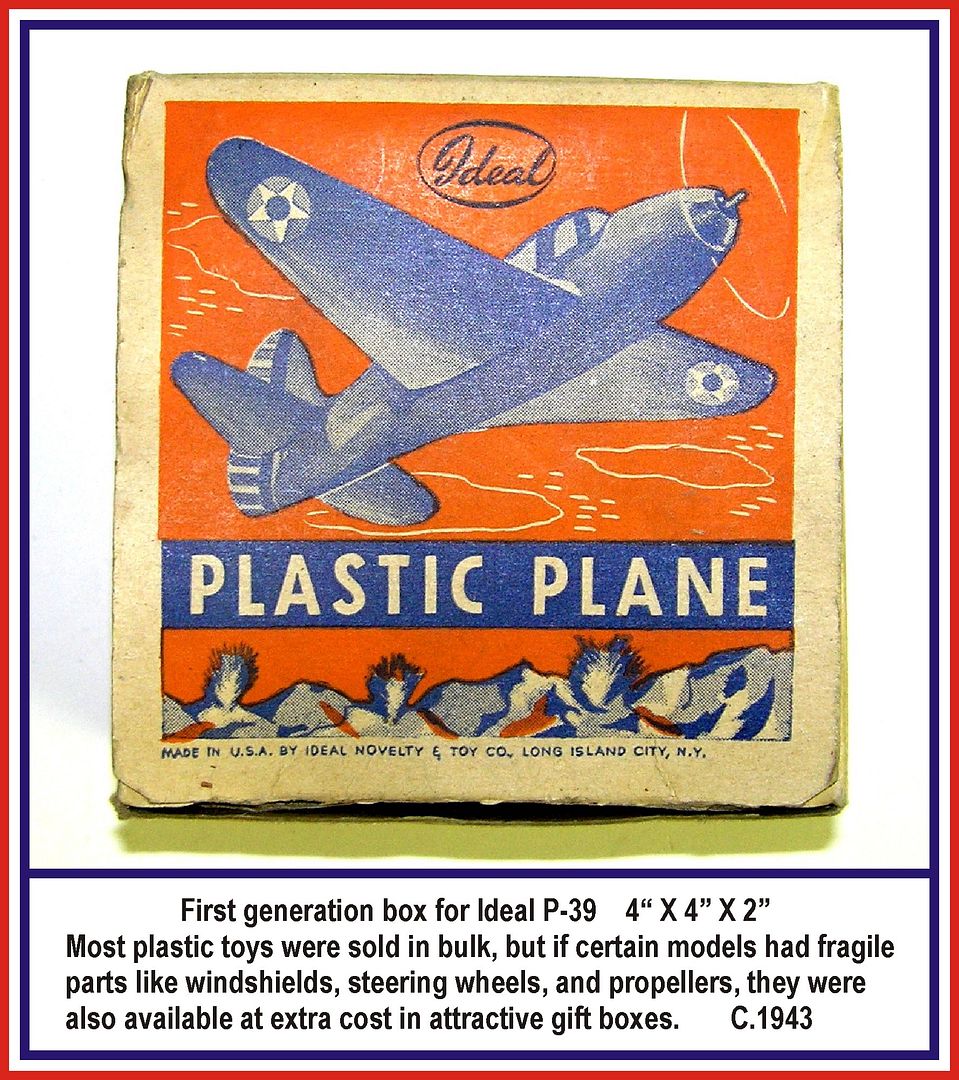

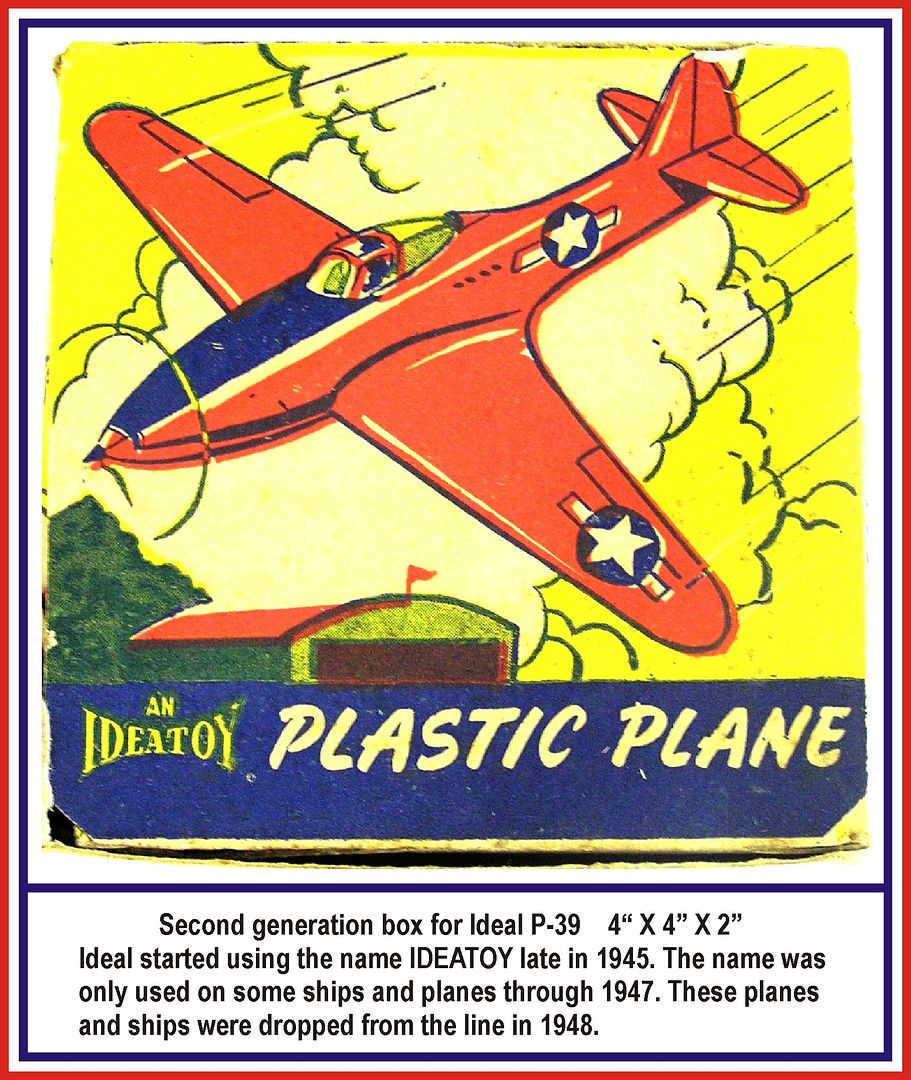

The demand for war related toys was growing at a feverish pace and stories of u-boats and dive-bombers made the headlines everyday. It was decided to start work on a cruiser, freighter, submarine, and airplane, which would be officially introduced at the March 1941 International Toy Fair held in New York City. The new line was a huge hit and by July the company was using all available molding capacity to produce the three ships and a Bell P-39 Airacobra.

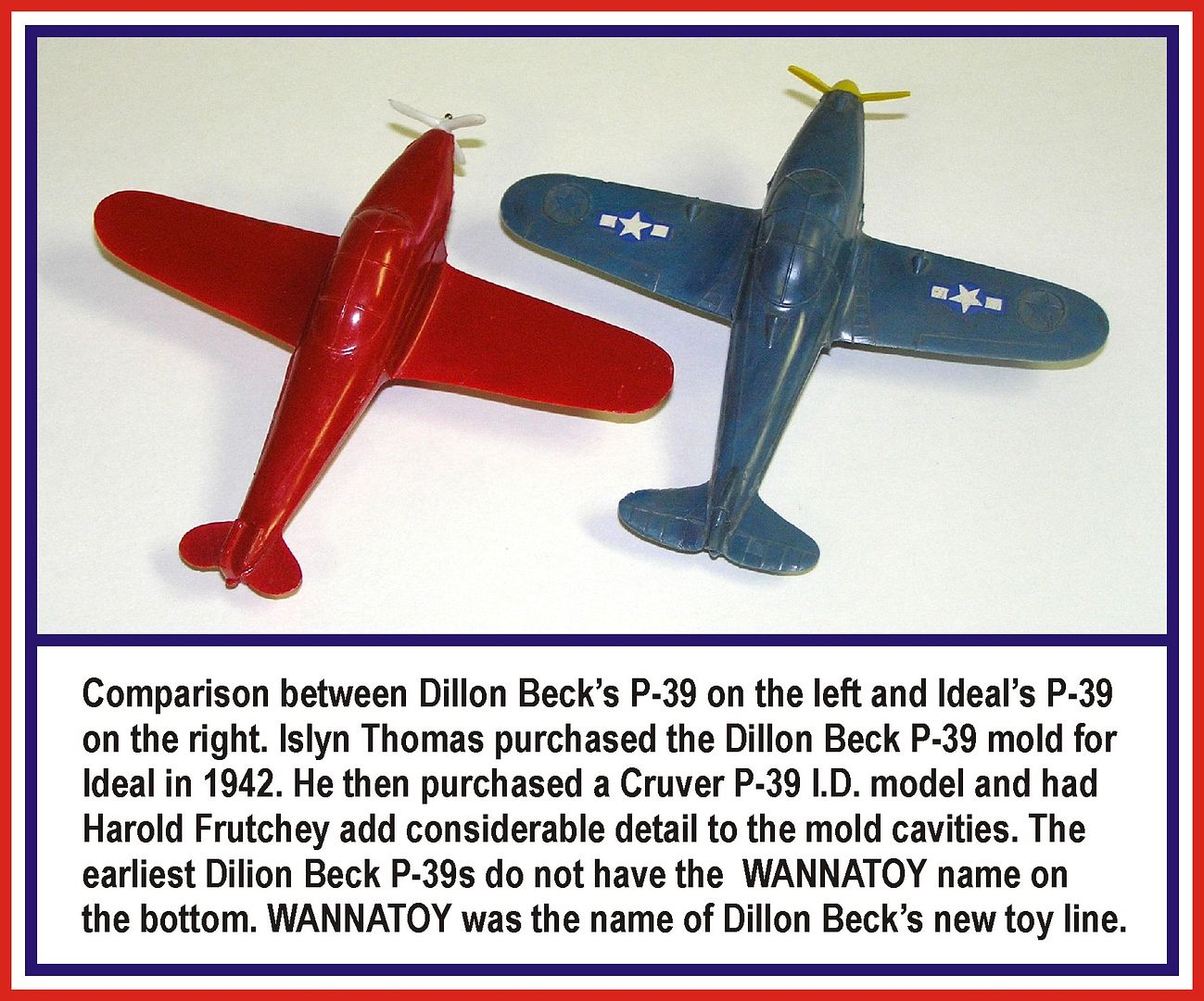

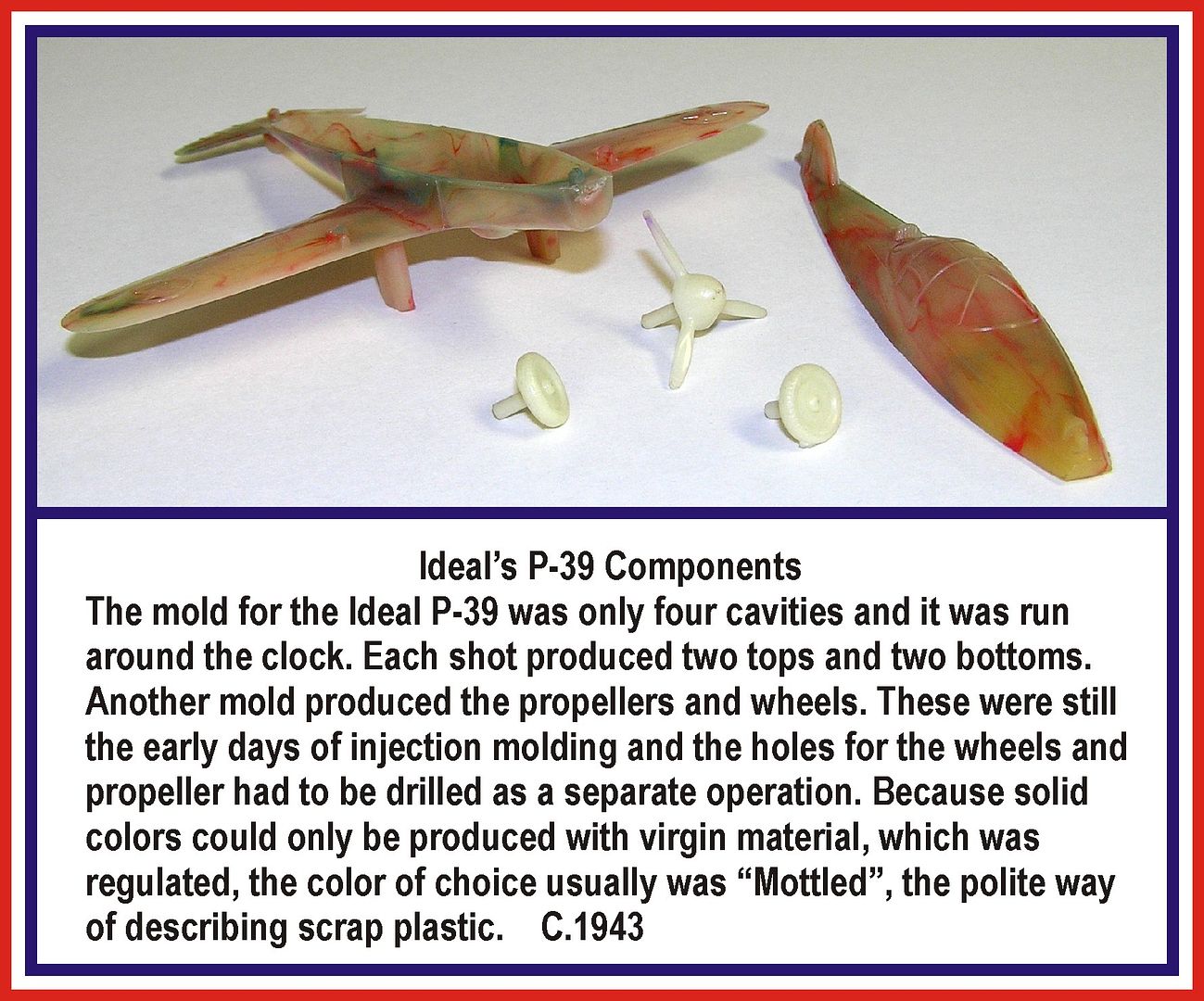

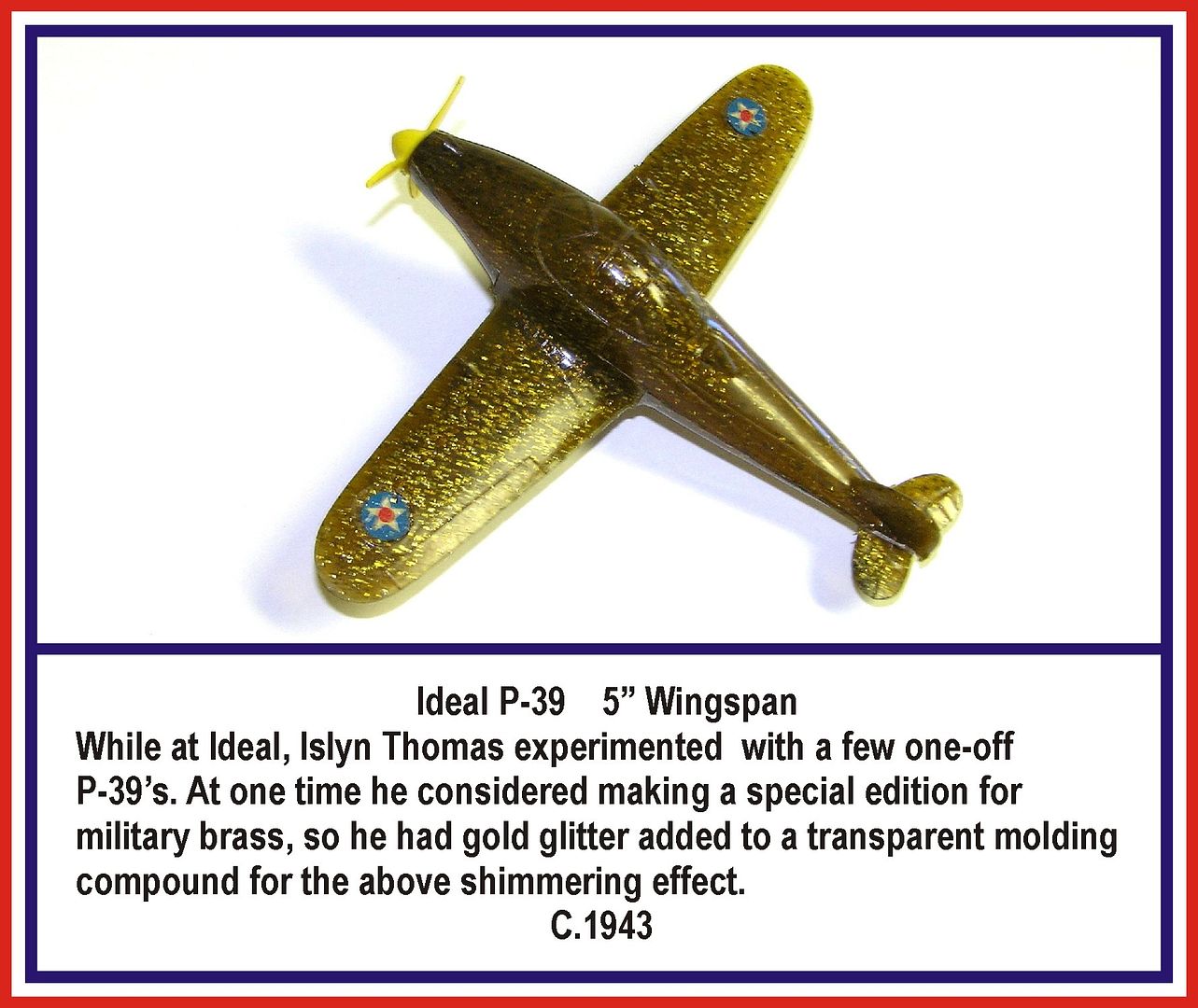

Dillon Beck's P-39 was a huge improvement over Kilgore's earlier DC-3. The P-39 had a two-piece fuselage, which gave it a nice weight and made it much stronger. Its thick wings didn't warp, and its wheels and propeller were made out of plastic, which eliminated the problem Kilgore had with deteriorating rubber.The only drawback was an acute lack of detail, which would be addressed when Ideal purchased and reworked the mold.

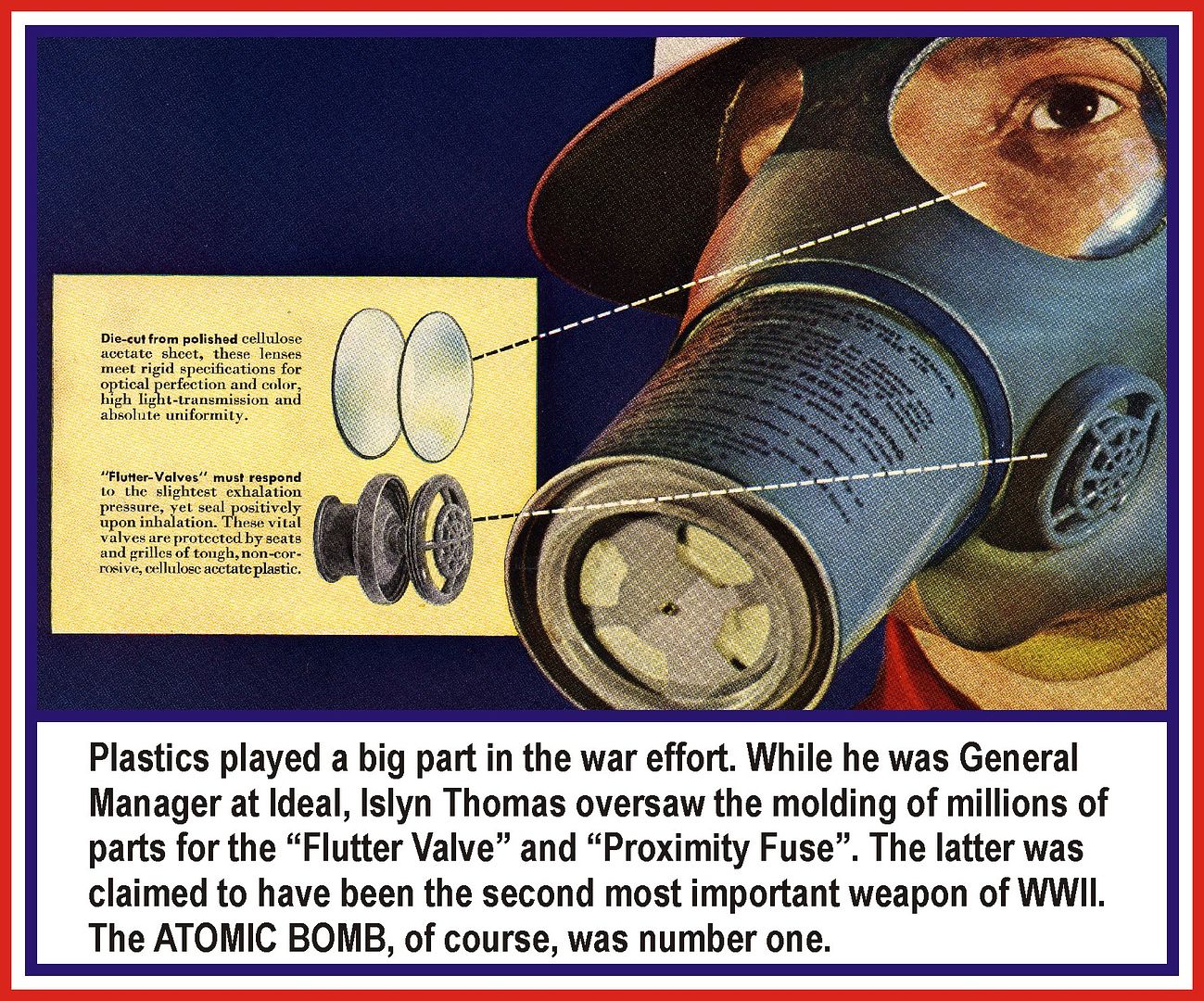

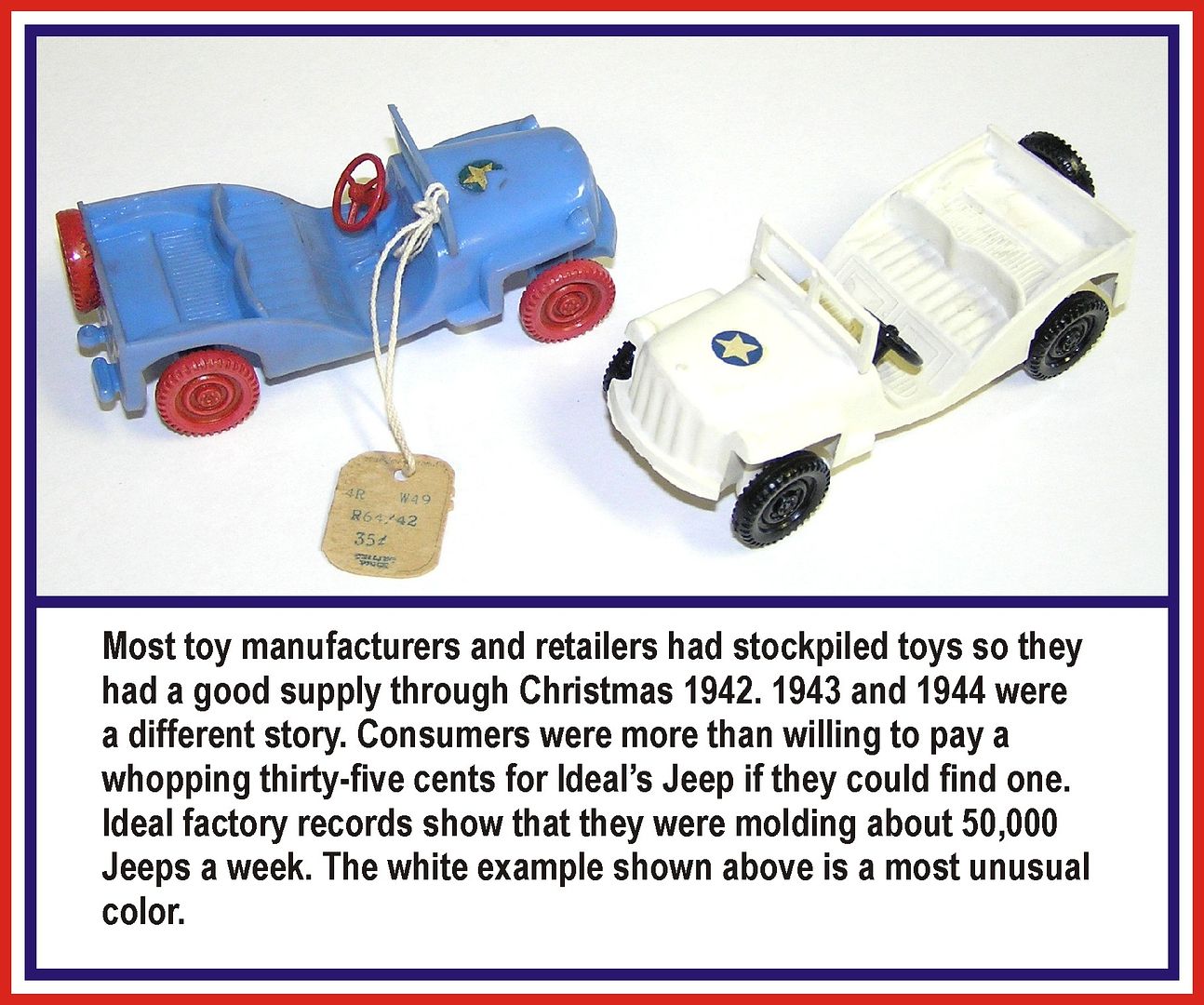

Dillon Beck's new toy line was called WANNATOY, a name inspired by their earlier fishing lure slogan. The WANNATOY name however, would only appear on their later production P-39s. Early production P-39s had no name at all, and their three ships only had the letters DB on their hulls. On December 7,1941 Japan attacked Pearl Harbor and the next day the United States and Great Britain formally declared war on Japan. Three days later Germany and Italy declared war on the United States. As expected, government restrictions on manufacturing soon followed as peaceful production ceased for all practical purposes and American industry geared-up to meet the challenge. As Germany rolled across Europe and Japan did the same in the Pacific, U.S. toy manufacturers were faced with a growing list of restricted materials. Toys made from rubber, tin, and steel were the first to go when these materials were added to the restricted list in March 1942. While the larger toy manufacturers and retailers had sufficient inventories on hand to get them through the 1942 Christmas season, it was obvious that substitution was going to be key to the industry's continued operation.

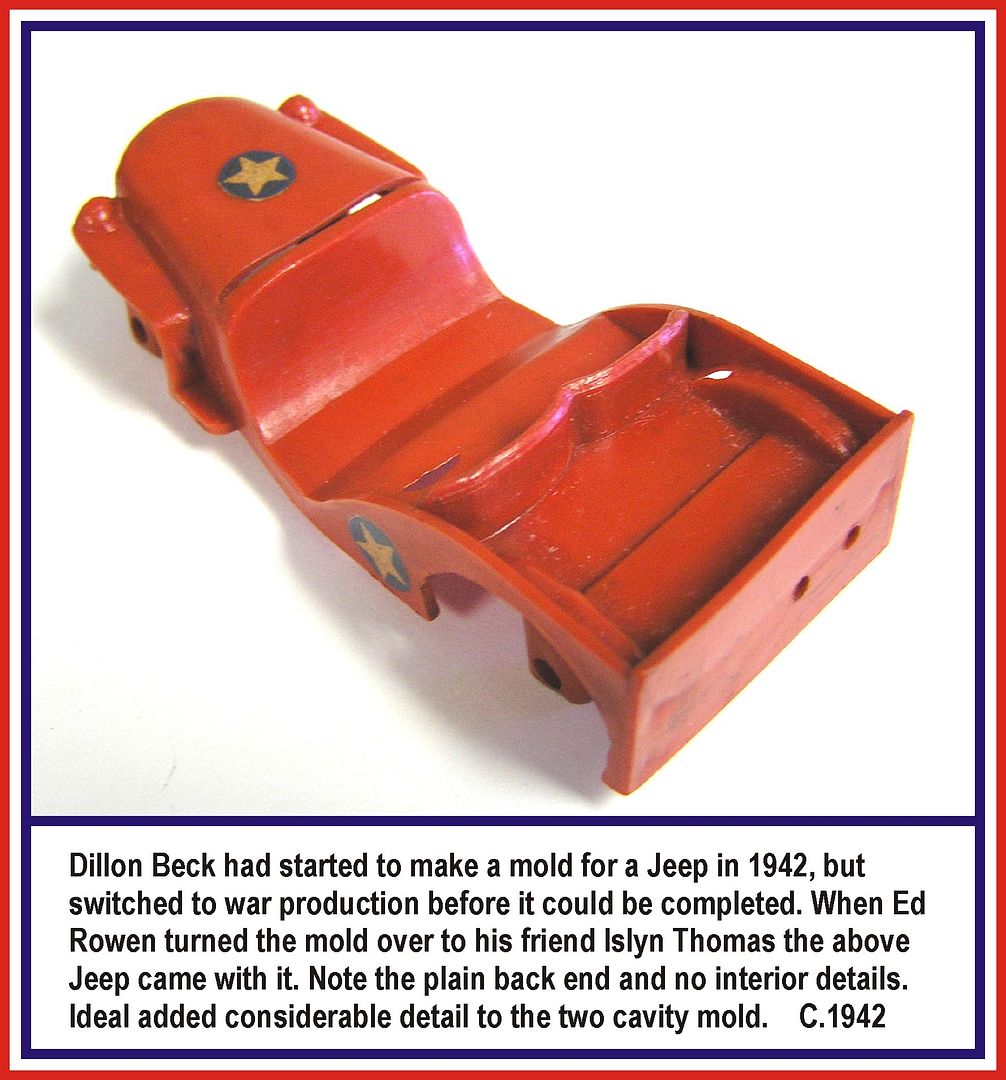

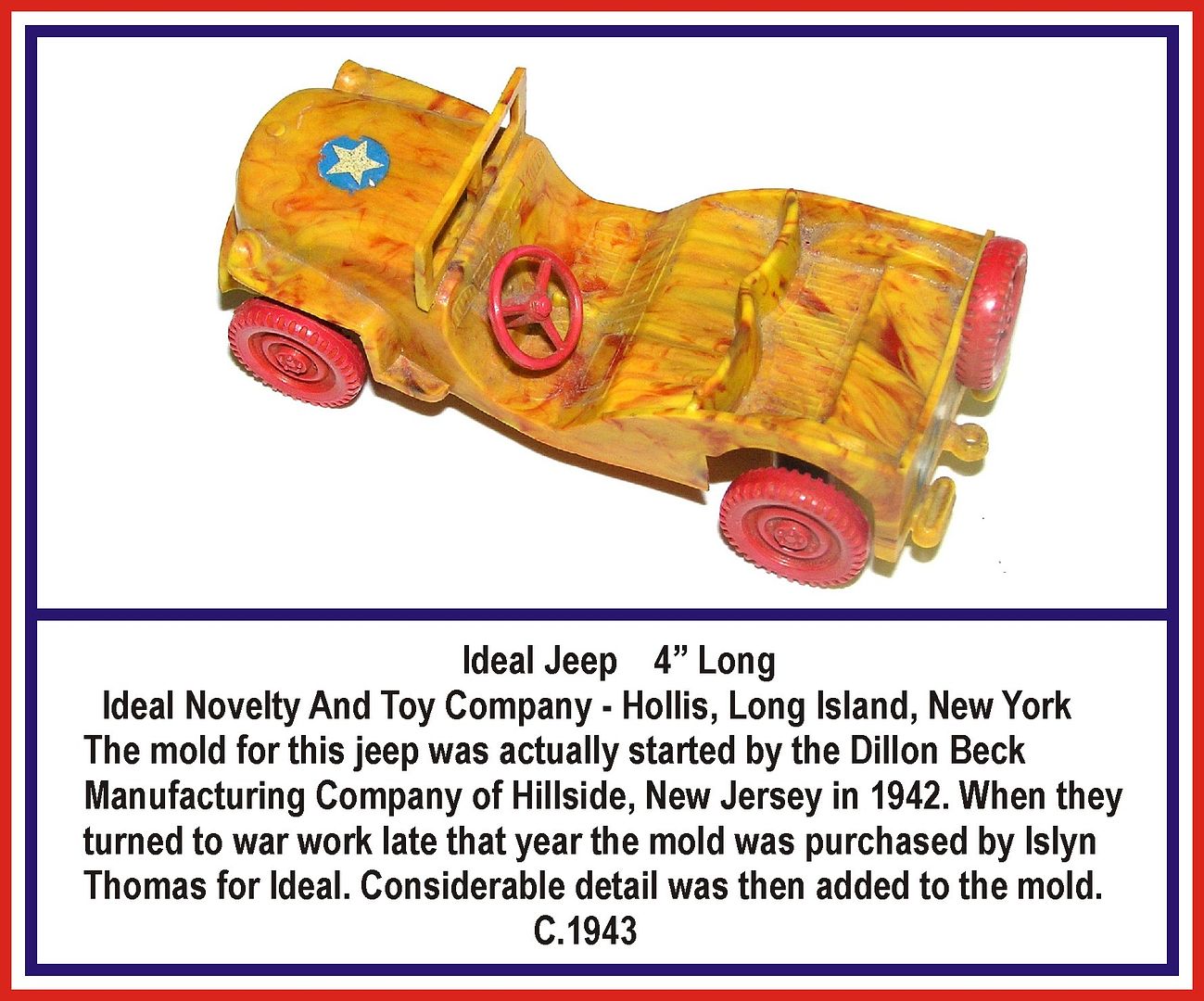

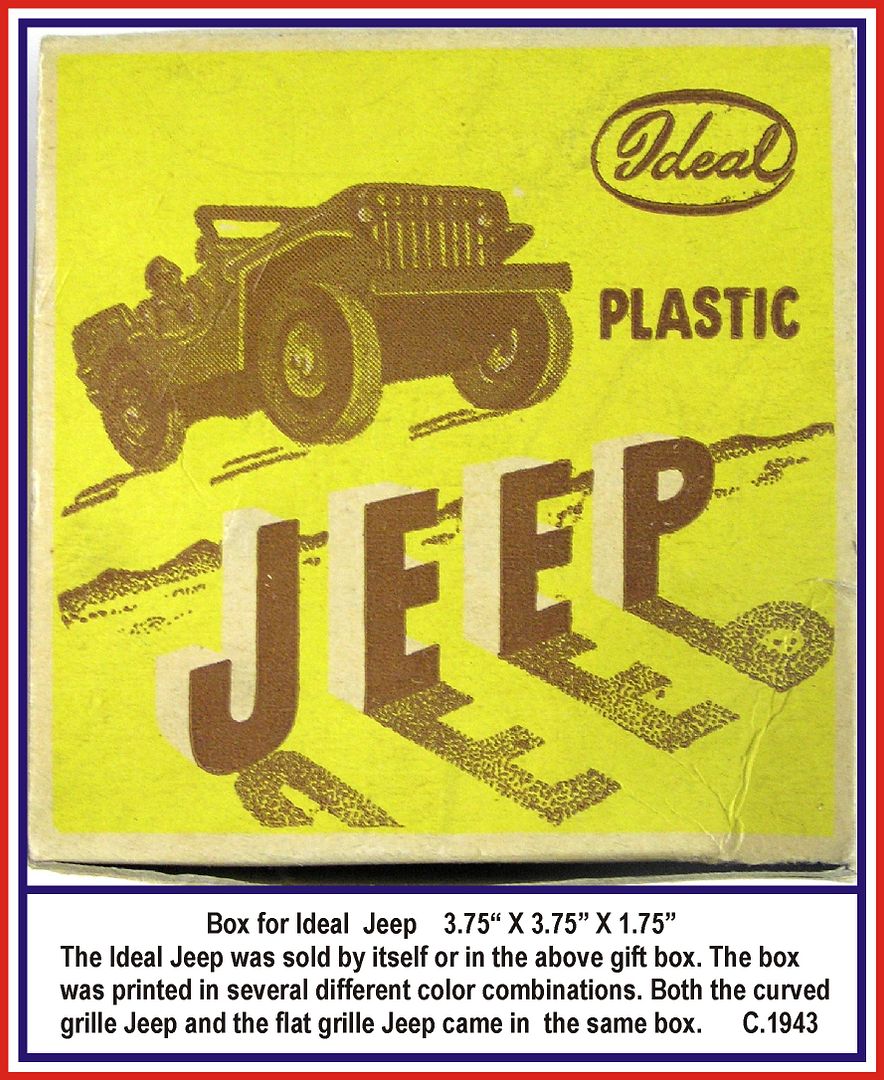

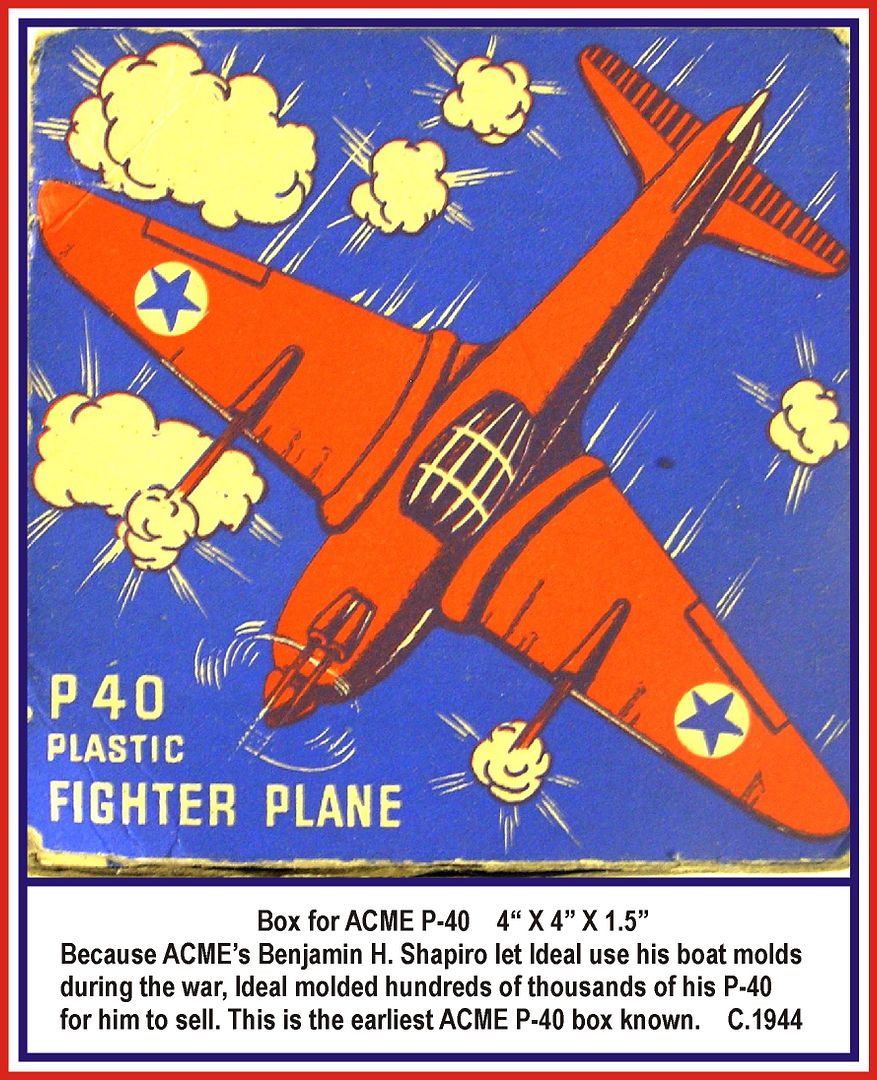

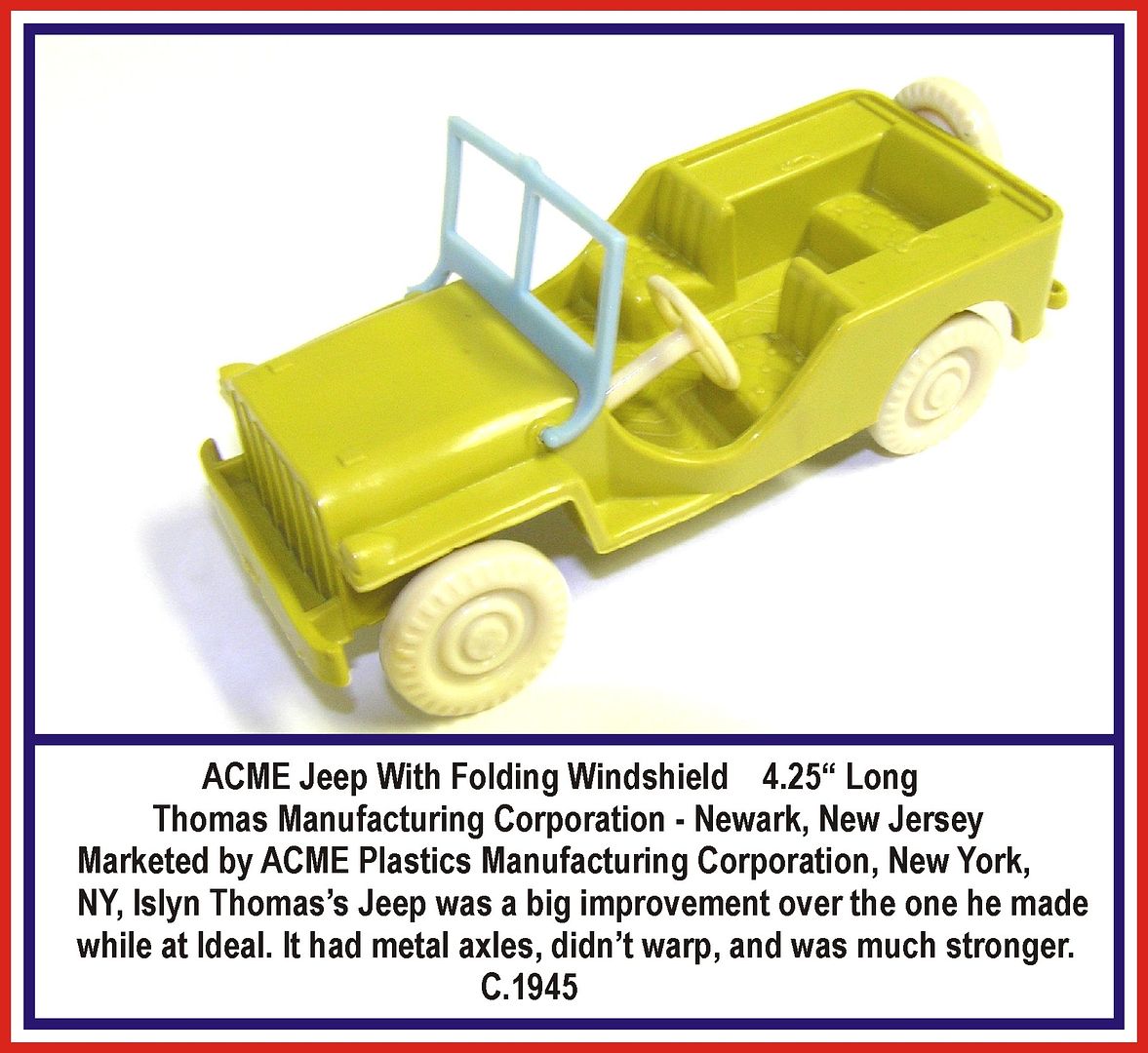

By the end of 1942, Dillon Beck had turned to 100% defense work, turning out molded parts for sextants, razors, and anemometers. As their production ceased for the duration, they turned the molds for their three ships over to Plastic Toys of Byesville, Ohio for a royalty, and they sold the mold for their P-39 and an unfinished mold for the first plastic Jeep to the Ideal Novelty and Toy Company.

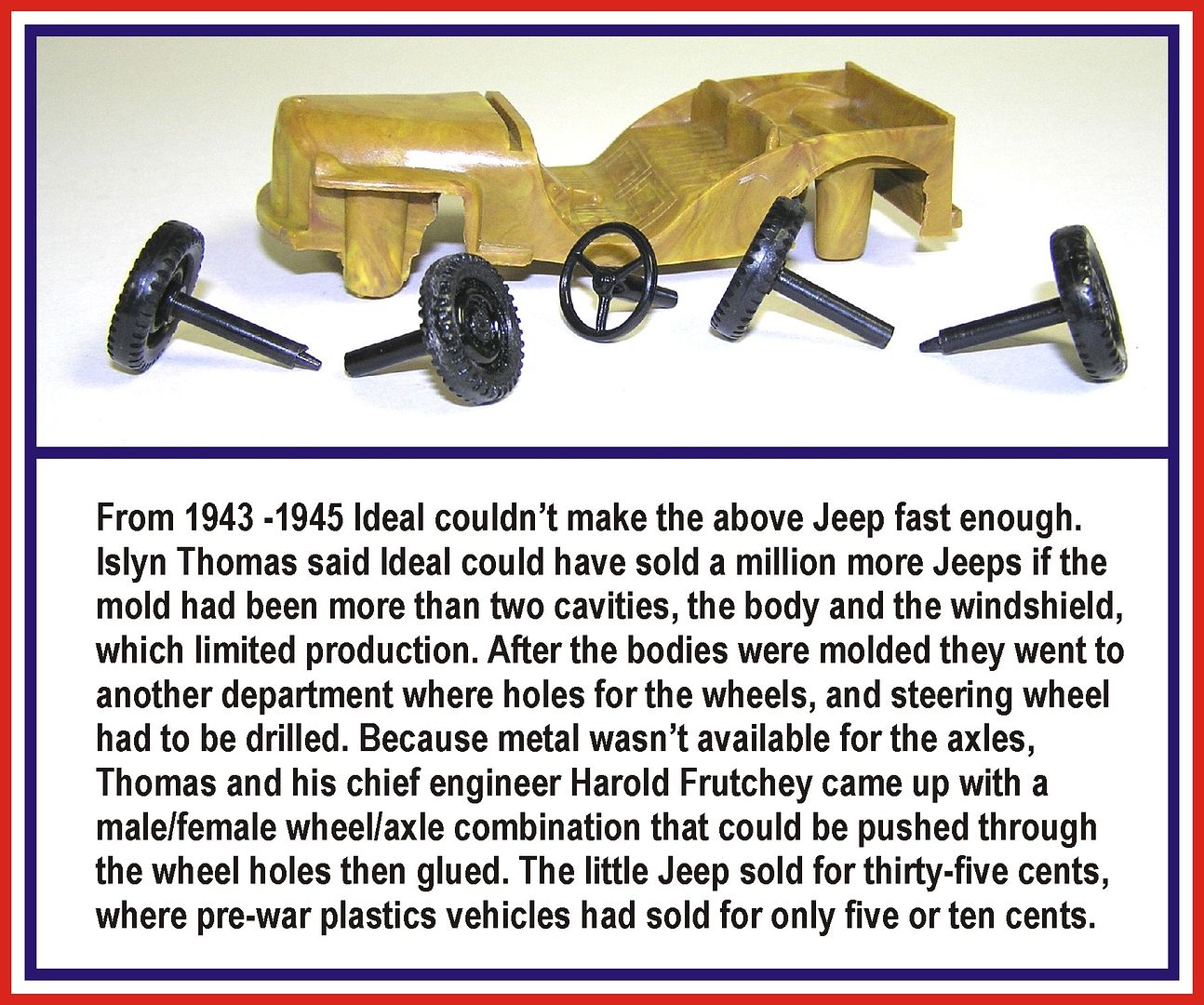

|

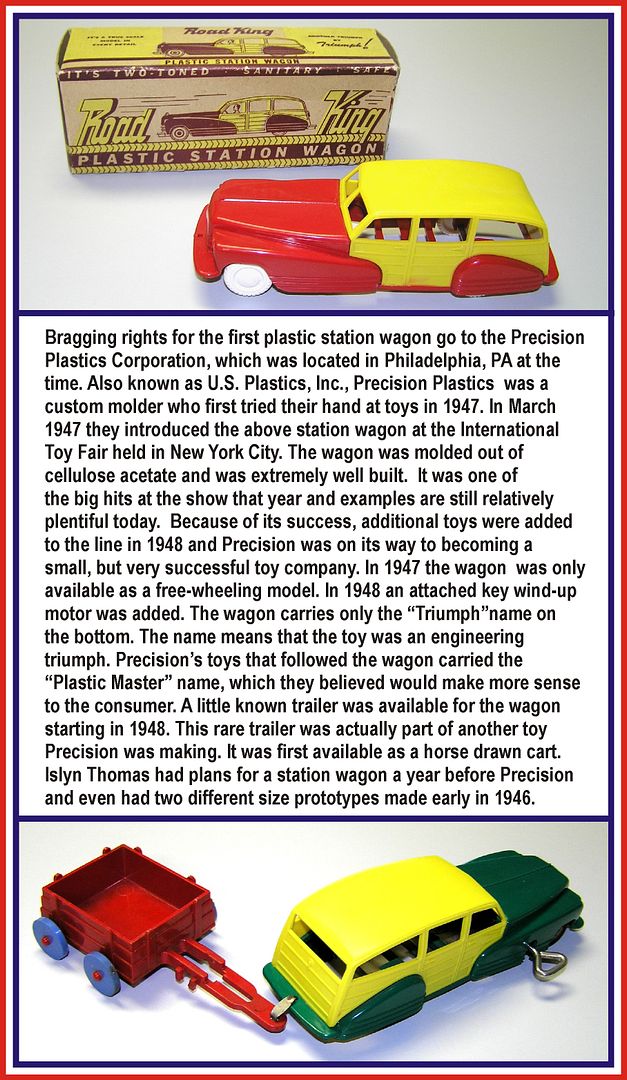

|

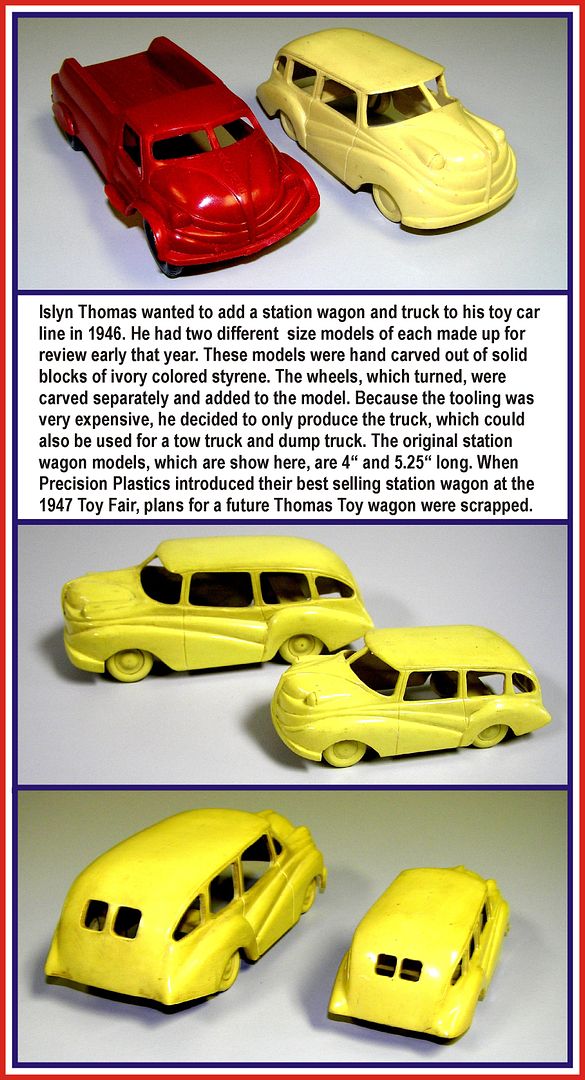

|